How to Start Installing Firestops

DISCOVERING AND INSTALLING FIRESTOPS WITH HELP FROM THE EXPERTS AT IDI

What is firestop? Fire stopping is using innovative or specialized products to seal around openings and between joints in a building to prevent the spread of smoke, hot gasses, or fire. These heavily tested products are given UL listings to show their ability to perform for extended periods in fire-rated wall or floor assemblies. The most common forms of firestop are intumescent caulking, putties, pillows and collars.

As an example: When installing firestop or intumescent caulking to fill a gap (annular space) between a pipe and the hole in the wall it goes through, it is tested to expand and fill the gap, even if the pipe were to melt away in a fire. Additionally, it must pass a second part of the test that shows it will not break apart and come out of the space when hit with a fire hose. This is to help ensure fire containment and protect responders attempting to extinguish the fire.

WHY SHOULD I CONSIDER INSTALLING FIRESTOP?

Unlike many other trades, firestop has a low barrier to entry. No large or specialized equipment is needed. In fact, in most states, becoming a firestop contractor does not require a license, and only requires a limited amount of training. As for the opportunity, every commercial building is required to be fire-stopped and compliance is definitely on the rise.

Years ago, very few inspectors checked all the holes in a building before issuing a certificate of occupancy. Then, as time changed, they walked around making sure penetrations were filled and normally looked for something red, like caulking, foam, or putty. Today, code departments want verifiable proof of what was done. This is why we see labels placed next to penetrations that can be scanned and checked to confirm the UL listing for the type of fire stopping that was performed.

IDI’S USER-FRIENDLY FIRESTOP INSULATION PRODUCTS

CAULKING

Firestop caulking is the most widely used product for UL-listed penetrations. The caulking comes in standard tubes, sausages, and buckets. Caulking can be latex or silicone. Installing this firestop is easy and comes in gun grade or self-leveling.

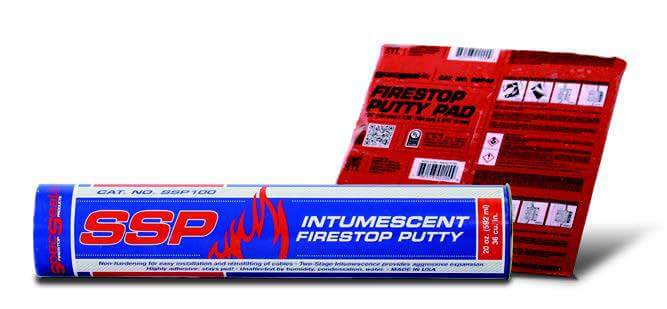

PUTTIES

When it comes to sealing cable penetrations or outlet boxes, putties and putty pads are the way to go. Putties conform easily and stay where they are placed.

COLLARS

Often, installing firestop around pipes will require a lot of intumescent product, which is what collars are used for. Collars are easily wrapped around a pipe and then secured to the wall or surface the pipe is going through.

FIRESTOP INSULATION TRAINING WITH IDI EXPERTS

IDI works with the best firestop vendors. When it comes to online or hands-on training, getting engineering judgments quickly, or simply needing a better solution to a jobsite problem, IDI is committed to your success. For more information on installing firestop, reach out to your local branch or contact us here at our MN headquarters today.

Learn more