As SPF applicators, we constantly change temperature settings, thanks to ever-changing substrate temps. I’ve been there. I’m from Michigan where it can go from winter to summer on the same day! It’s easy to get frustrated and demand the SPF manufacturers make one type of SPF that doesn’t require changing temperature settings, but unless we are spraying in a controlled environment, we know this is an unrealistic wish. Even if there was a spray foam that didn’t require a change in temperature settings, there would be consequences like loss of yield. Because we have to deal with changing substrate temperatures, adjustments to SPF temperatures are extremely important, not only for your day-to-day success, but for your checkbook at year’s end.

How Heat Adjustments Work on the Job Site

Here’s a quick story of how heat adjustments played a big factor on a job site I was recently on: I was working with some new applicators on the main level of a house, spraying plywood walls and making perfect foam. Then, we moved to the basement (concrete walls). I knew things were about to change, but I remained quiet to see how the new applicators would react.

As soon as they started spraying, you could clearly tell the foam was different. It was slow to react and seemed to be taking more product to get to the thickness needed. What changed? Well, the answers were right in front of them. THE WALL! The substrate went from plywood to concrete, and the air was noticeably cooler. A quick check with a laser thermometer showed them the wall was 20 degrees cooler. And with concrete being a heat sink, that hurt them even more. We stopped and I talked them through these changes, and the effects they had on their foam. We bumped their temps up to account for the changes and were back to installing great spray foam insulation.

What Is the Temperature Range for Spray Foam Insulation?

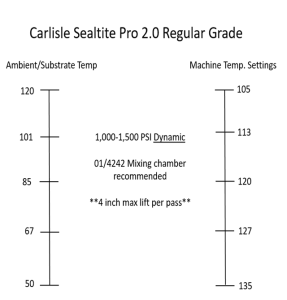

Temperature ranges for spray foam vary from product to product. Remember, all products are proprietary to that specific manufacturer. This is why it is so important to get the application guide for the specific product you are spraying before getting to work or assuming the range should be the same as an alternative product. The product application guide will give you all the information you need to get the best product. It will have the minimum and maximum substrate temperature allowances for the specific blend you are spraying, equipment temperature and pressure setting windows, storage temperature requirements, and maximum lift limits.

Temperature ranges for spray foam vary from product to product. Remember, all products are proprietary to that specific manufacturer. This is why it is so important to get the application guide for the specific product you are spraying before getting to work or assuming the range should be the same as an alternative product. The product application guide will give you all the information you need to get the best product. It will have the minimum and maximum substrate temperature allowances for the specific blend you are spraying, equipment temperature and pressure setting windows, storage temperature requirements, and maximum lift limits.

Compiling all of that information and creating a temperature ladder is the way to go; ambient/substrate allowances on the left, and recommended temperature settings on the right. Target the wall with your laser to determine the substrate temperature, and move across the ladder to get your starting temperature settings. It’s not going to be exact, but it will give you a starting point each day. Then pay close attention to the foam and make adjustments when you need to.

When Should You Use High Heat for Spray Foam?

As we discussed above, when your substrate cools off, we need to speed the reaction up. This can be done by increasing the heat settings on your equipment.

Using high heat settings typically happens during the transition months from summer to winter products. When we get to the low-end substrate allowances for summer products, you have to use high heat to keep the reaction speed up. Once we switch to winter blends, we’ll be working with a more aggressive catalyst package. That material is sped up chemically to deal with the cold which allows us to back our settings back off.

You will never find a “one size fits all” solution when spraying foam. At the end of the day, the best advice I can ever give is to get the Application Guide for the material you are spraying to learn and understand that specific blend.

“Reading the Foam”

This is why we always talk about “reading the foam” at our national training events. Your temperature adjustments should always be made on the information you receive from the wall.

Spray foam manufacturers put temperature ranges on their application guides to help, but as substrates warm up, we need to slow the reaction down with our rig settings. Conversely, as the wall cools off, we speed the reaction up by changing the temperature. When you don’t make these changes, it lowers yields and wastes both time and money. Maintaining density is where your dollars are, and the temperature range settings play a huge part in maintaining proper density and getting the most coverage out of your spray foam.

If you have questions about dialing in your material, take advantage of IDI’s technical team. They are some of the best SPF educators in the country when it comes to training your team and maximizing your insulation materials. If you don’t know your IDI Tech Rep, or want more information on spray foam or any of the other insulation products we sell, contact your local branch manager or sales rep at IDI. Our goal is to help you succeed. So don’t forget to adjust those temperatures and go make great Spray Foam!

Written by TJ Miller, Spray Foam Technical Training Manager at IDI Distributors