Long Tab Banded Insulation Systems

Why long tab banded insulation systems

With the increased stringency of building energy codes, long tab banded insulation systems have become very popular in the construction of metal building systems.

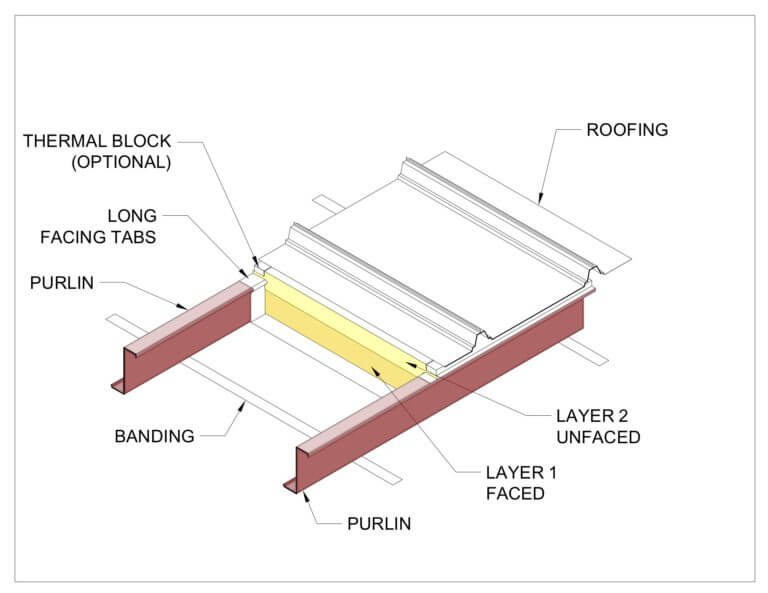

A long tab banded insulation system uses two layers of fiberglass metal building insulation. The first layer is laminated and is installed between the roof purlins. The second layer is installed perpendicular and over the top of the roof purlins.

WHY WOULD I USE A LONG TAB BANDED INSULATION SYSTEM IN MY METAL BUILDING?

Long Tab Banded assemblies meet or exceed most ASHRAE and IECC building energy codes. The R-30 roof insulation system is installed from the roof deck area and when installed properly, will give a good appearance.

The system provides required U-values very similar to fabric liner systems but at a lower cost.

BENEFITS OF USING METAL BUILDING LONG TAB BANDED INSULATION SYSTEMS

Long tab banded insulation offers a high R system that effortlessly resists heat flow and easily provides a cool interior. Here are just some of the benefits of using long tab banded insulation:

- Meets or exceeds more ASHRAE and IECC Energy Codes

- A cost-effective way to maximize the amount of insulation installed between the purlins and the girts.

- Other trades still have easy access to the bottom flange of the purlins. This makes it easy to install items such as sprinkler systems, and electric fixtures.

- Fiberglass insulation is the lowest cost per R-value—much more cost effective than rigid board or insulated metal panels.

OUR PROCESS FOR LONG TAB BANDING

The pricing and processing of an order for a Long Tab Banded System can be difficult. IDI has access to trained professionals that will review the metal building’s final drawings to create an insulation cut-list that assures that the faced insulation matches the wide to each purlin spacing.

From estimating to final cut-list, IDI can assure that you get the right materials for your long tab banded project.

WHAT IDI HAS TO OFFER

IDI can provide the entire long tab banded insulation system and connect you with contractors who practice seamless installation.

- The metal banding is available in white or black.

- We provide the self-drilling screws required for installing the banding

- For the faced layer, the customer has the choice of 11 different facings.

- The unfaced layer is also supplied by IDI.

COMMON QUESTIONS ABOUT LONG TAB BANDED INSULATION

This depends on the height of the purlins. We need to provide enough material to run the height of the purlin and then up and over the top. For example, with 8” deep purlins, we would provide 2-12” long tabs.

For new construction, it will be much easier to install the product as the roof is installed. However, long tab banded systems have worked well in retrofit situations.

Both products provide excellent installed U-values. The major difference is that the fabric liner system is installed below the roof purlins, and therefore the roof purlins are no longer exposed. The Long Tab Banded System is installed between the roof purlins.