Have you, or your customers wondered what benefits come with each different type of spray foam insulation? The different forms of this insulation are used to insulate, air seal, strengthen, protect, provide buoyancy and prevent moisture drive in both residential and commercial buildings. It has a comparable R-value to other types of insulation, but also features other characteristics that can make it a great product for your job.

Below you’ll learn about the different types of spray foam insulation, what they’re used for and why. As we explore these topics, remember this is only scratching the surface. As a leader in the insulation industry, we are committed to providing the best SPF products to contractors as well as support to those of all experience levels. Just ask anyone who’s come to IDI’s training classes how it made their spray foam businesses safer, more professional, and more profitable. Read the below insights to get a glimpse of why the best in the business turn to the insulation experts at IDI for all of their spray foam needs.

What Are the Different Types of Spray Foam Insulation?

There are two most widely used spray foams, normally referred to as open cell, which is low density, and closed cell, which is medium or high density.

Open Cell Spray Foam Insulation

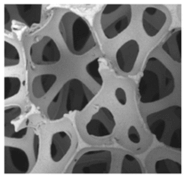

Open cell spray foam’s name represents the product perfectly. During the manufacturing process, a lot of steam is produced. That steam forces its way out of the foam leaving a lot of broken or fractured cells behind. The resulting foam is typically softer, and more pliable. Think of these foams like a sponge. Their cell may be open, but at a certain thickness, they provide air sealing and insulation and are pretty good at sound attenuation.

When open cell spray foam is exposed to enough vapor drive, it will absorb some moisture and vapor can pass through the foam as it seeks to find a condensing surface. Once it finds that surface the vapor can rot or compromise the durability of the structure. Because of this, the building code requires a class I or II vapor retarder to be placed on the interior side of vapor permeable insulation in zones 5 and higher. Check out Insulation Institute’s article on vapor retarders for more information on retarder use with insulation.

Here are a few more facts about open cell spray foam that will help you decide if this foam is right for your particular needs:

- Open cell is 0.4-1.6lbs/cubic foot and typically have R-values from 3.5- 4.5 per inch and are 90% open cell content or higher.

- Also referred to as low density foam.

- Newer hybrid formulas, while still being considered open-cell formulations, have achieved R-values above 6/inch.

- Designed for interior applications.

- Prized for their ability to provide both insulation and air sealing in one application.

- Because the cells are open, these foams are not vapor retarders.

- Traditional open cell spray foam must be protected anywhere there is a potential for moisture to be present.

- Higher-density hybrid products can be a vapor retarder when applied thick enough.

Closed Cell Spray Foam Insulation

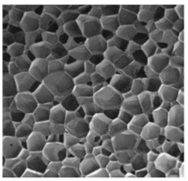

Closed cell blends, on the other hand, have a gas that is used in their manufacturing process, and retaining that gas is part of the goal. Just like the gas in windows, trapping these gasses provides a higher R-value than trapping air. Additionally, since the cell walls are intact and tightly held together, the resulting foam is more dense and rigid. Closed cell foams have a similar feel to the dashboard in your car.

- Closed cell foams dominate the market in northern climate zones because of the colder temperatures and vapor drive in the winter months. They are used in almost any area including wall cavities, ceilings, unvented attic assemblies, floors, crawl spaces, and concrete walls.

- Used when structural support, greater Rvalues, or eliminating vapor drive is needed.

- Closed cell foams typically range from 1.7 – 3+lbs/cubic foot.

- R-values range from 5.2- to over 7.2 per inch with a closed cell content of 90% or higher.

Medium Density Closed Cell:

- Medium Density spray foam’s R-value ranges from 1.7 – 2+lbs/cubic foot.

- Typically used in interior applications that call for maximum R-value’s or where cavity depth is limited.

Highest Density Foam

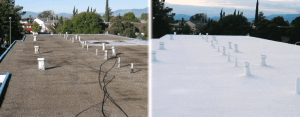

- 2.7-3+ lbs./cubic foot.

- Mainly used in spray foam roofing or other exterior applications.

- Great for reducing thermal bridging and adding strength and R-value to roofing.

- This type of spray foam has also been proven to increase racking strength. If you live in “tornado alley” high density closed cell spray foam may be the way to go for your project even if it isn’t a roofing application.

- Combined with the right building design, closed cell foam helps prevent wind uplift. Spray Foam Magazine has published research to support this idea.

Making The Right Choice

Remember, spray foam insulation has a wide range of uses such as insulating, air sealing, strengthening and protecting structures, providing buoyancy and preventing moisture.

Achieving any of these may call for a specific product, but which should you use, and where should you use it? Do you need medium-high density closed cells, low-density open cell, or maybe high temperature or slow rise pour foams? Each has unique characteristics, and some for very specific applications.

Selecting the right foam is going to depend on the project you are working on and what you’re trying to achieve. Work closely with your Builder, HVAC contractor, code official or building inspector, to make sure you are using the right products in the right applications.

If you need further insight, contact your local IDI location, where they have more resources and insight into their local markets. If you have other questions on Spray Foam, Spray Foam equipment, or any of the other products IDI offers, reach out to us. Remember, we offer classes and on-site education as well as spray foam materials and equipment. We look forward to earning your business every day!